Design and Passion

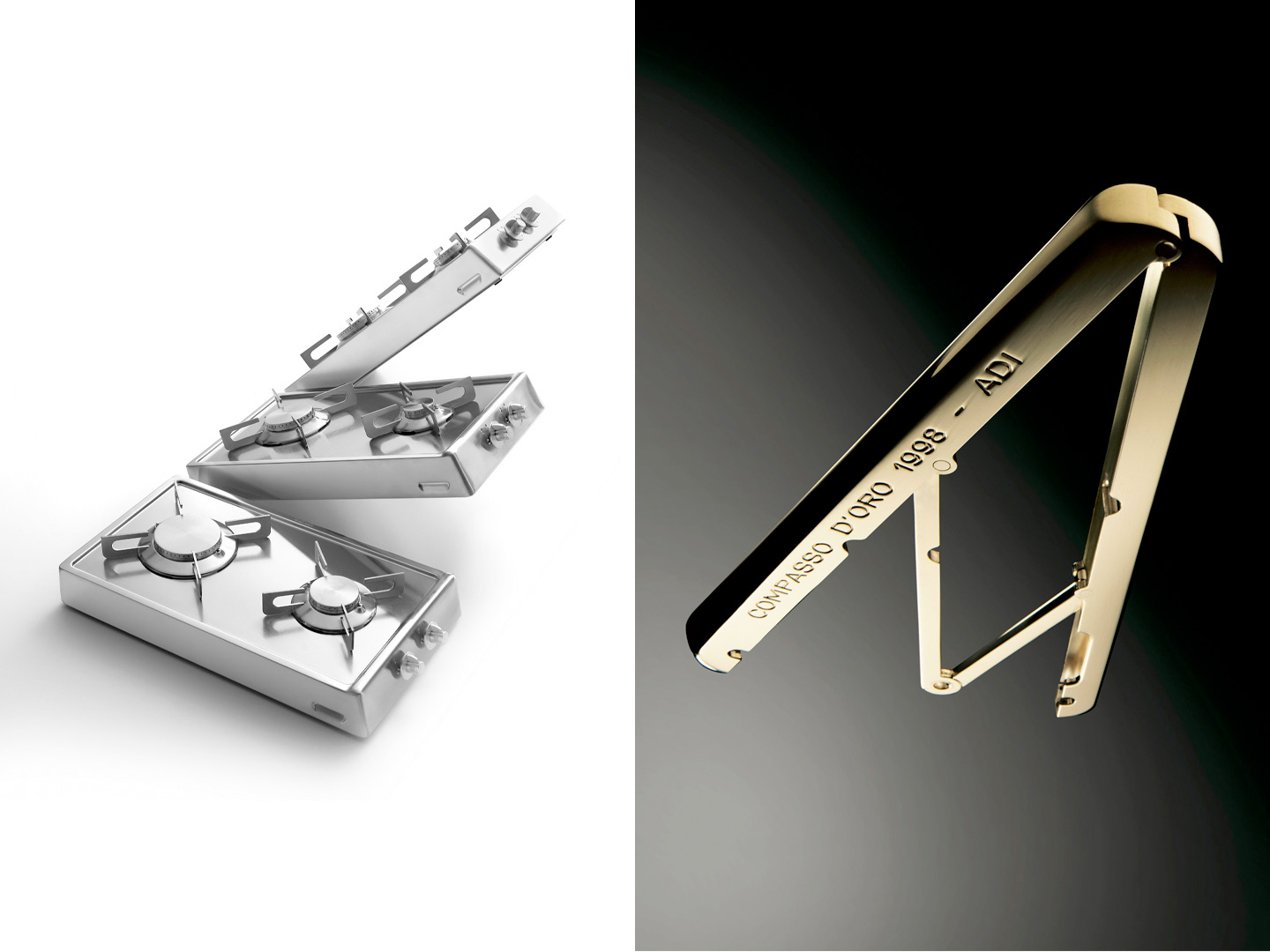

Alpes-Inox has existed for 70 years. This means that the market, and two generations of people, have recognized and still appreciate the value of its products. This value is the result of the passion and the design talent of Nico Moretto, entrepreneur, designer and founder of the company, that now is managed by his sons Aldo and Bruno. A talent recognized first by the customers, and later by the critics, whose approval took the form, in 1998, of the prestigious “Compasso d’Oro” award of the Association of Italian Designers (ADI) for the flip-up hob, along with an honorable mention for the electronic exhaust system. Alpes-Inox products are instantly recognizable, because their design exists outside of passing trends and fashions. This design has evolved over the years, but it has never changed direction in pursuit of ephemeral commercial success. The only “vogue” that interests Alpes-Inox is one based on functional quality and safety. This can be seen in the carefully designed details and rounded forms, for easy use and cleaning. «The only serious evolution of the aesthetic question is in the direction of ethics; I am thinking of ergonomics, safety for adults and children, energy savings, eco-compatibility. We’re not interested in “novelty for its own sake”. We proceed in a logical manner, continuing to perfect what already works. We shouldn’t forget that a kitchen is a durable asset, to be replaced only two or three times during the entire lifetime of a home or a person. So, there is no reason to do things hastily». These are words that start at the surface, and move toward the most profound aspects of design.

Ethics and Material

Words that speak of choices, true qualities, materials, ethics. The first choice is the material used, not the one that is “in” this year, nor a “new” material, nor a “mixture” of the natural and the synthetic: just steel. But not just any steel. Alpes-Inox uses AISI 304 stainless steel, a high-quality, practically invulnerable material, very hygienic and very easy to clean. The 19/10 alloy, together with the finish, guarantees the exclusive “silver tone”, and ensures that the product will be absolutely “stainless”, or oxidation-proof. Two properties, above all, make this the ideal material for the kitchen: durability and hygiene. It is highly resistant to detergents, solvents, disinfectants. Its maximum hygiene rating is the result of the absence of any protective coating beneath which germs and grime can accumulate as a result of wear; the compact surface, without any porosity, leaves no havens for bacteria, dust particles, liquids, detergents, meaning that the foods that come into contact with the surface cannot be contaminated or altered by such agents. For all these reasons, and due to its characteristics of easy maintenance and cleaning, stainless steel is specified by law for the kitchens of public spaces, restaurants, hospitals, etc. Apart from this exceptional material there is the choice to design according to the most advanced contemporary sensibilities: a focus on the safety of the user, on risk prevention-based studies of ergonomics and posture for those who work in the kitchen. Next, there is a refusal to oblige people to make use of technologies based on programmed obsolescence, a major consumer trap; the emphasis is on durability and reliability of products over the course of time. Finally, the design approach involves a sense of civic responsibility, avoiding waste of water and energy, favouring recycling and proper disposal of refuse.

Industry and Craftsmanship

Although its design excellence places it at the forefront of the sector, and is greeted with international acclaim, Alpes-Inox continues to define itself as a metallurgical/mechanical industry. An industrial firm that is not obsessed with the idea of growth, although it makes use of avant-garde technologies to work in the field of home appliances, a field dominated by giant multinational corporations. In fact, Alpes-Inox feels that its size is ideal for the kind of painstaking attention that only a family-run business can guarantee. These principles are also a part of the local spirit in Bassano del Grappa, a city between the plains and the mountains in Veneto, a region in which the history of art and craftsmanship is alive and held sacred, where people are proud to be industrious, honest, responsible. Certain types of workmanship stand out, illustrating a particular mind-set: just look at a blown glass vase in the midst of plastic containers, listen to the sound of a flute by a highway.

Fine craftsmanship means the creation of a work of material culture designed for people who are capable of understanding and recognizing that culture. These are not just industrial strategies, but ways of being and seeing; to proceed in this way implies a delicate balance between industrial expertise and traditional methods. One example of this balance is the “silver” satin finish that makes Alpes-Inox products different from all the others. The raw steel receives a special treatment to achieve the “silver” tone, as the company calls it: the surface is brushed, gradually, uniformly, to remove all signs of earlier manufacturing processes and all possible imperfections. The result is a shiny, luminous colour, similar to silver: equal and uniform in all the points of each product, and in all of the models. This is a costly, time-consuming procedure. But it is just one of the many choices Alpes-Inox has made that sets it apart from other manufacturers. This is a company that has its own style, appreciated by both old and new clients.